C/F manufacturing process

-

Step 1 Approval of Specifications

Drawing up and approval of Fabrication Specification with customers

-

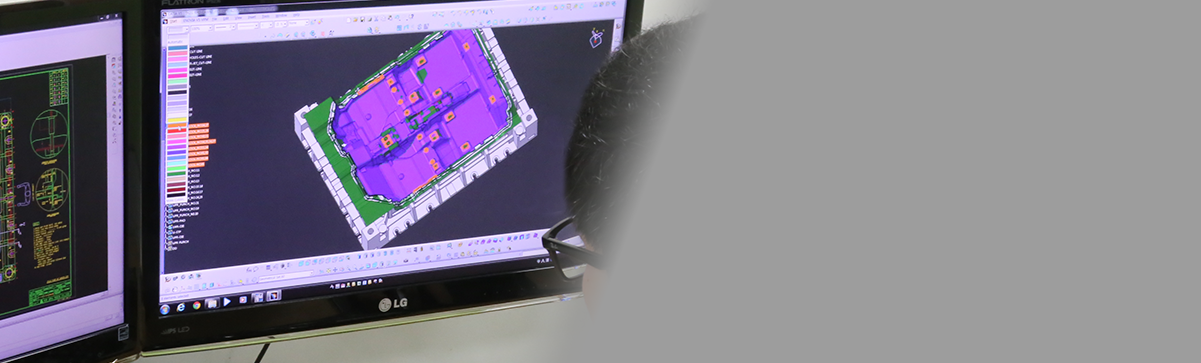

Step 2 3D modeling

Design 3D modeling and structure of checking fixture in accordance with Specifications and product 3D Data

-

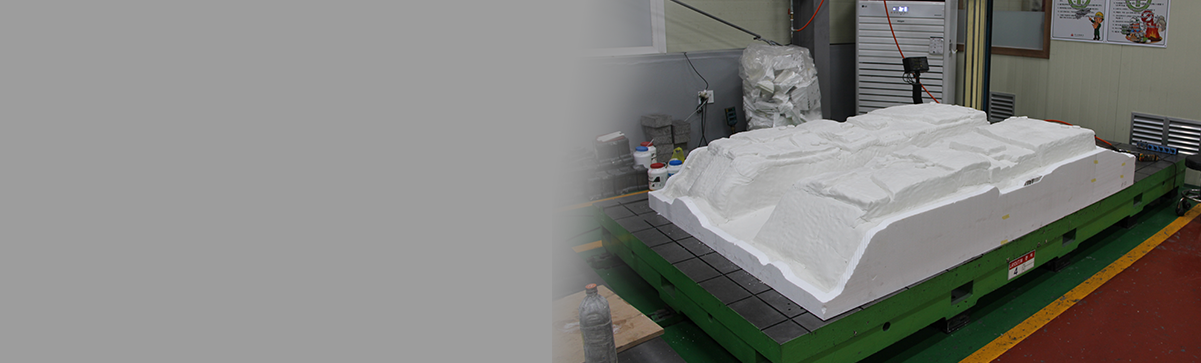

Step 3 Temporary form and steel pipe fabrication

Laminating type

① Pattern fabrication -> ② Apply a release agent on the surface of pattern -> ③ Laminating a workable resin ->

④ Base frame fabrication -> ⑤ Fixing and welding together with base frame and laminated resin -> ⑥ Pattern removal

Panel type

① Temporary form fabrication -> ② Base frame fabrication -> ③ Welding the steel plate and pipe -> ④ Form fixing

-

Step 4 CNC work

Machine the temporary form, which is laminated with workable resin after creating tool path using WORK NC program

-

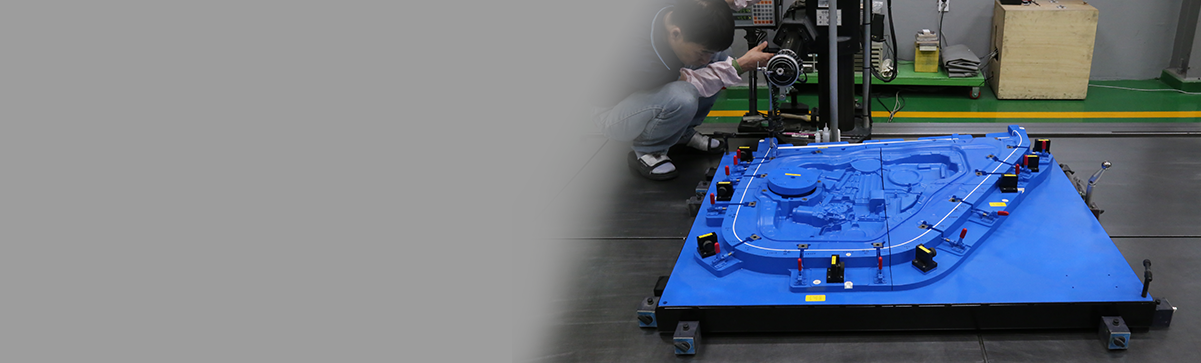

Step 5 Assembly and CMM inspection

Inspect the outer surface, assembling parts, line marking and datum points on checking fixture

-

Step 6 CNC work

Machine the surface of FC or AL casted mold using WORK NC program on 3D CNC machine

(Rough→Semi-Finishing→Finishing machining) -

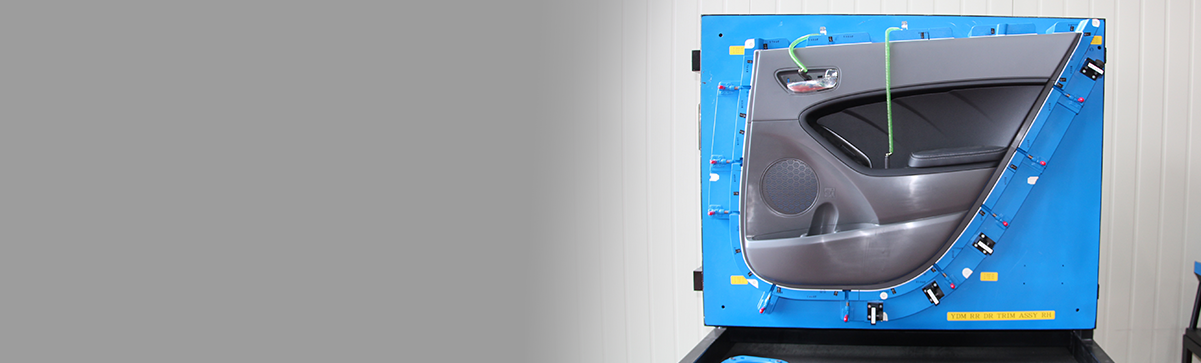

Step 7 Dimension inspection

- Mount the finished product on the checking fixture and check dimension in accordance with approval drawings

- T, L, H point marking